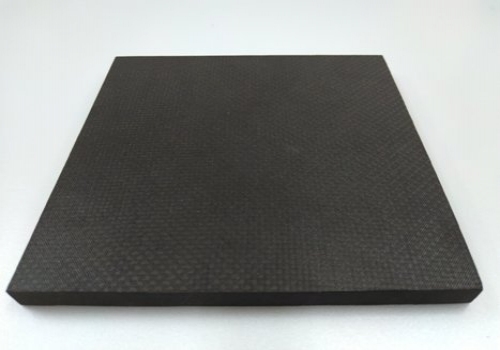

Robustoca Technology Co., Ltd. (Robustoca) was founded in 2015. We are specialized in the production of the carbon fiber products, and providing the OEM/ODM/JDM service for worldwide customers. Not only we provide the products for medical application but also extend to the applications of automotive and high temperature industrial field. Nowadays, we have improved and developed highly skilled techniques in VaRTM (Vacuum assisted Resin Transfer Molding), VI (Vacuum Infusion) and etc. We also offer a prior design in service to comply with the tier 1 equipment provider, and fit the different application scenario.

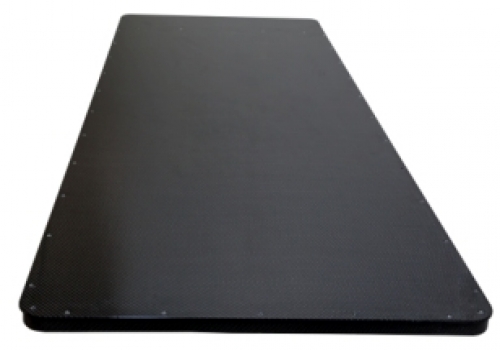

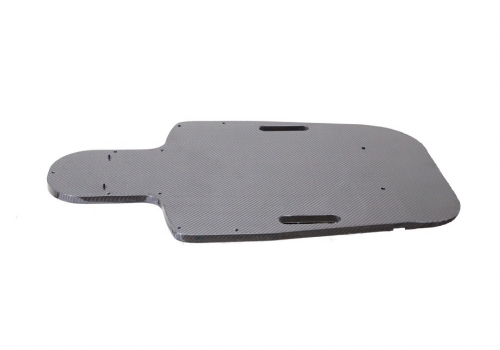

Further to medical application, our carbon fiber product can be used in

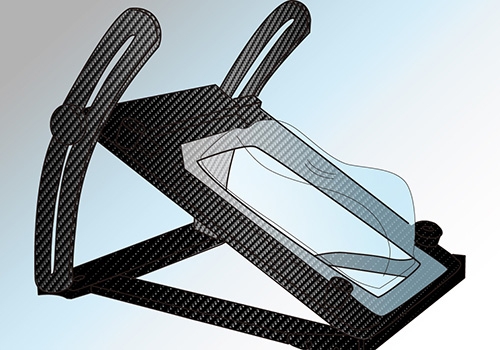

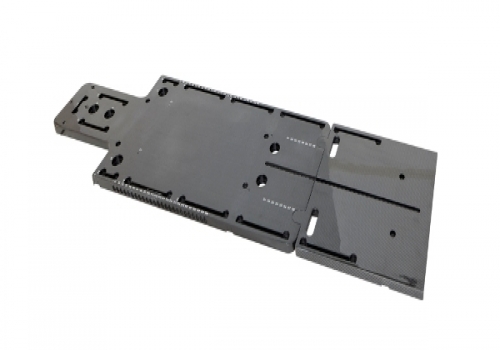

- Radiation therapy for treatment tabletops; various immobilization and support devices

- Surgical or operating table that offer minimal attenuation, maximum image quality and reduced radiation exposure. Ideally suited to cardiovascular, orthopaedic and trauma operations.

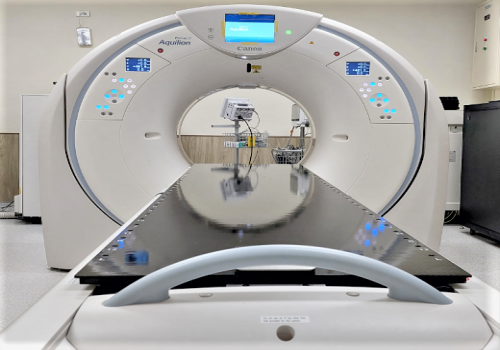

- Computed Tomography (CT) imaging tables.

We are pleased that you are interested in our products. We sincerely invite you to explore the Robustoca website to learn more about our company and products.